Proper Use & Care of Our Tube Cleaner Equipment

Proper Use & Maintenance

The Putzmaus® is an efficient and very effective cleaning tool that can improve fuel consumption and significantly increase boiler efficiency. Like all precision-engineered tools however, all Putzmaus® models must be used properly and undergo regular maintenance.

Here are some important guidelines to help you get the most out of the Putzmaus®:

Before Your First Use on Boiler Tubes

Use care when unpacking and storing your Putzmaus®. Be sure to remove all the wrapping from the hose before the initial use. When storing the Putzmaus®, take care to protect the air hose connector by replacing the safety cap supplied with your unit.

Pipes must be cleared of any extreme build-up of deposits before the Putzmaus® can be effectively applied. The Putzmaus® is designed as a cleaning tool that is used every 3 to 6 weeks. It is not a repair tool, and as a result can be damaged by use in pipes that are severely clogged or almost completely blocked.

The Putzmaus® works best when the diameter of the brush is matched with the inside diameter of the tubes. This is very important as the brushes always have to be larger than the tubes, how much larger is dependent on the size of the tubes. Measuring the exact inside diameter of the tubes is crucial. We strongly recommend consulting us first about the diameter of tubes you are planning to use the Putzmaus® on.

Preparing Your Automatic Tube Cleaning System For Use

Keep a supply of new brushes on hand. The brushes on the Putzmaus® wear over time, with the average brush designed to clean 500 metres of pipe. If the brush becomes too worn down, the Putzmaus® will not function properly. Make sure to order replacement brushes to have available as needed.

The Putzmaus® works best when continually supplied with compressed air at 180-280 litres per minute at a pressure of 8 bars.

Always make sure that compressed air is clean and free of particles by using a particle separator. In addition, we recommend that the water separator of the maintenance unit be emptied and the oil container be refilled with compressed air machine oil at regular intervals. The main piston of the Putzmaus® has a clearance of only 0.03 mm, and so it is important that there are no foreign particles, water, or a lack of oil in the compressed air. These can cause severe damage to your Putzmaus®.

Operating Your Putzmaus® Tube Cleaning Machine

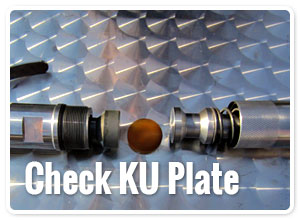

Check the KU disk after every cleaning. The KU disk is a key part of the Putzmaus® that will wear down over time. Make sure that it is checked regularly – after every cleaning – and that it is replaced immediately once it begins to break down.

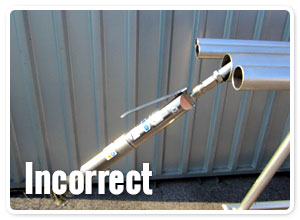

Only hold on to the apparatus and not the high-temperature-compressed air hose. When using the Putzmaus®, holding on to the hose rather than the Putzmaus® apparatus, can cause the coupling that joins them to come apart.

Place the Putzmaus® in the pipe end with the lever depressed. It will automatically move down the pipe and return on its own without further assistance. Do not push the unit down the length of pipe as this may cause unnecessary wear on the unit. You may; However, add a tape marker to the hose as shown below to determine the total distance the hose needs to travel in the tube.

Maintaining Your Putzmaus® Boiler Tube Cleaner

If however, the Putzmaus® becomes stuck in a pipe, the high temperature-compressed air hose can be used to carefully pull the Putzmaus® out. If this is necessary, check the coupling before further use.

Put a few drops of oil on the compressed air connection after every use. After each time that the Putzmaus® is used we recommend putting a few drops of oil on the compressed air connection and letting the apparatus run for 2 to 3 seconds. It is also helpful to rub the outside of the Putzmaus® with oil. Doing this will protect both the inner and outer surfaces from corrosion.

Only use the maintenance unit that comes with each Putzmaus® on that specific apparatus. Your Putzmaus® comes with a maintenance unit that is designed exclusively for that particular model. Using the incorrect maintenance unit can result in significant damage that is not covered by the warranty.

Each maintenance unit must be checked and cleaned at least once a year. When operating, make sure that there is a minimum of one drop of oil supplied to the compressed air every 5 to 15 seconds. You can check this by watching the drop through the glass of the oilier. Following these simple guidelines and performing regular maintenance will ensure that you get the most of the Putzmaus®. It will also guarantee that your Putzmaus® remains covered by warranty.